VHB Tape for Low Surface Energy Plastics: What You Need to Know

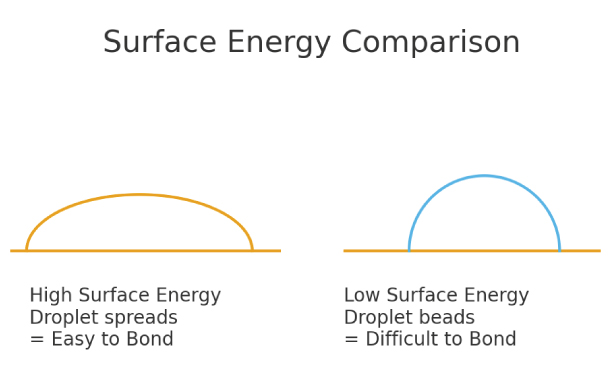

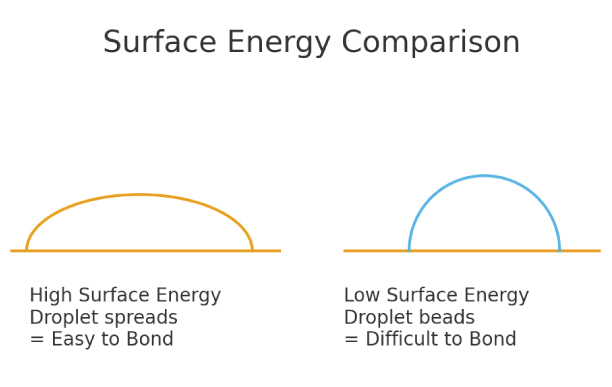

Bonding low surface energy (LSE) plastics like polypropylene (PP), polyethylene (PE), thermoplastic polyolefin (TPO), and powder-coated surfaces has always been a challenge. These materials have slick, non-porous surfaces that most adhesives simply can’t grip. If you’ve tried using standard double-sided tape or even traditional glues, you’ve probably seen the bond fail over time — or never hold at all.

So, what’s the best solution for bonding these difficult plastics?

The answer is VHB tape designed for low surface energy substrates.

Why High Bond LSE Tape Works on Low Surface Energy Plastics

Unlike standard tapes, VHB low surface energy tape uses a specialized acrylic adhesive that can “wet out” and flow into the microscopic surface texture of LSE plastics. This allows the tape to form a strong, permanent bond without the need for primers, surface treatment, or other modification steps that slow production down.

Where VHB Tape for LSE Plastics is Commonly Used

VHB low surface energy tapes are used across industries where durable plastic bonding is required, including:

| Industry | Typical Applications |

|---|---|

| Automotive | Trim parts, moldings, bezels, interior & exterior plastic components |

| Appliance & Electronics | Housings, covers, speaker enclosures, device frames |

| Industrial / OEM Assembly | Plastic panels, guards, molded enclosures |

| Sign & Display | Plastic sign faces, mounting brackets, display components |

Why LSE-Specific VHB Tape Performs Better

Standard “high bond” tapes are formulated for medium to high surface energy materials (like metals, glass, and rigid plastics). While they may stick to a low-surface-energy plastic at first, the bond will typically fail as the adhesive doesn’t “wet out” as well on these surfaces.

LSE-grade VHB tape solves that problem with:

-

Higher adhesive flow

-

Increased surface wetting

-

Optimized long-term holding power on slick surfaces

Choosing the Right Tape

If you’re bonding plastics like:

-

Polypropylene (PP)

-

Polyethylene (PE)

-

Thermoplastic polyolefin (TPO)

-

Powder-coated or painted finishes

Then you need a VHB tape specifically engineered for low surface energy substrates — not just any double-sided foam tape.

Shop VHB Tape for Low Surface Energy Plastics

Find the right tape for your application here:

https://highbondtapes.com/industrial-hb-tape/low-surface-energy-tape